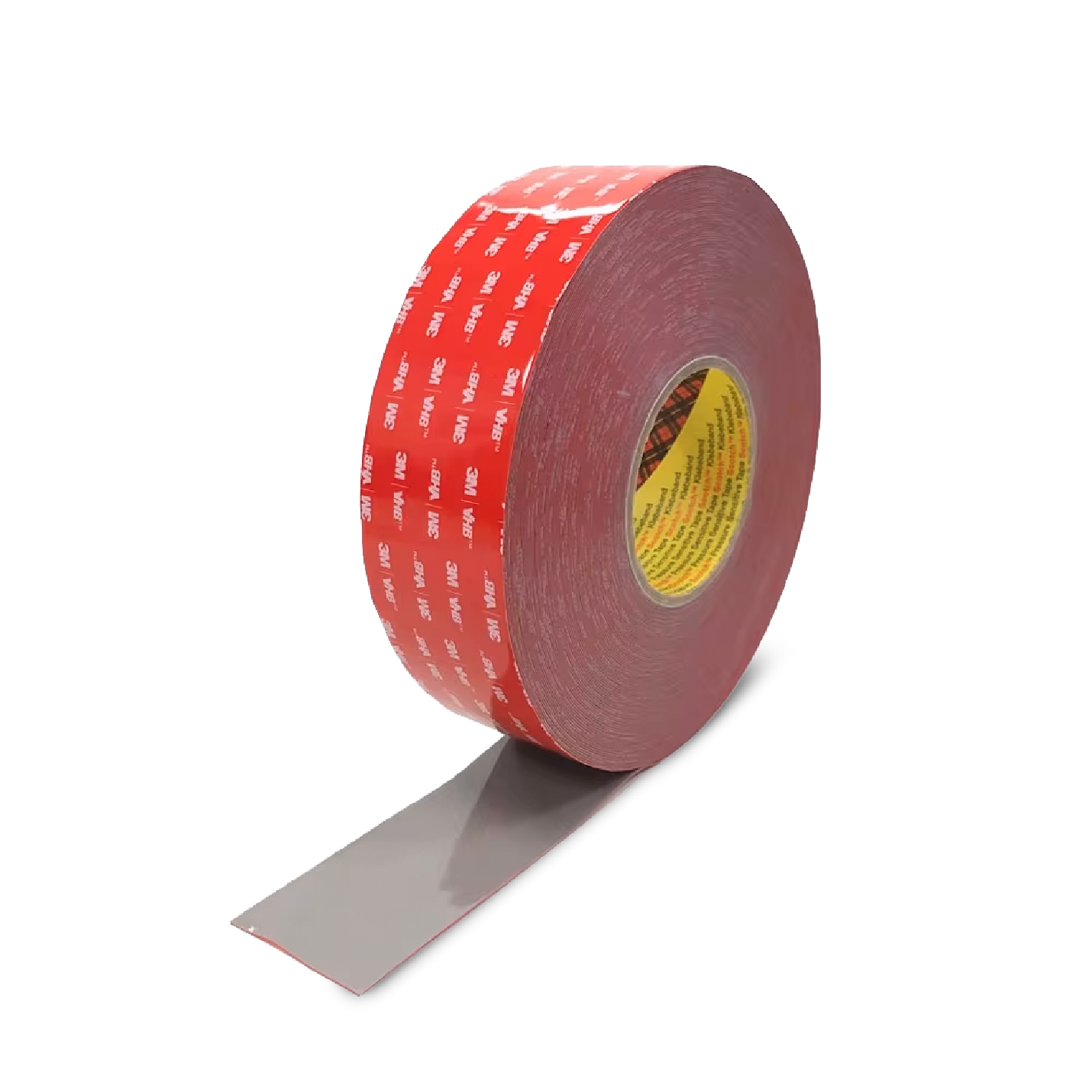

Custom 3M™ VHB™ Tape Solutions

Looking for industrial-level adhesive strength, consistent performance and an aesthetically pleasing finish? The solution is as simple as applying a piece of tape. 3M™ VHB™ Tape has multiple properties rolled up in one product. Not only does it deliver a bond with the power to replace rivets, this high-performance pressure sensitive tape also seals and cushions.

Lean on our expertise to identify the best product in the line to match your substrate and conditions. And we’ll die cut it to fit your part with utmost precision.

3M™ VHB™ Tape: Unroll Exceptional Innovation

Build better products with this versatile bonding solution die-cut for your needs.

Elevate aesthetics

Replace rivets, welds and mechanical fasteners with smooth lines with near-invisible bonding.Enhance performance

Acrylic adhesive forms a reliable bond that gains strength with time.Streamline assembly

3M™ VHB™ tape requires no cure time and reaches handling strength upon contact.Improve resistance

Holds up to hot, cold and cycling temperatures, UV rays, moisture and solvents.A better user experience

Specialty foam core can dampen sound vibration and reduce metallic wear and tear.Why 3M™ VHB™ Tape?

3M™ VHB™ Acrylic Foam Tape was originally introduced in 1980 to bond panels to ambulance frames. Boasting a remarkable strength to take the place of screws, rivets, spot welds and liquid adhesives, it was a game-changer for engineers and product designers, unlocking possibilities for every industry.

How does 3M™ VHB™ tape work?

In short, it’s all about the foam. The visco-elastic properties absorb energy and stress so they are not transferred to the bond line. Long term stress in the bond line is dispersed in the acrylic foam core. The foam provides the strength and protects the bond!

iDentify the best 3M™ VHB™ tape for the job

The 3M™ VHB™ Tape family comes in a range of foams, adhesives, colors and release liners to provide versatile bonding solutions that enhance your product’s design and function while saving you time and money.

iD Products is a 3M™ Preferred Converter with direct access to 3M™ technical experts. We’ll apply our expertise in VHB™ Tape to help iDentify the best product for your application.

Our technical analysis will factor in the following properties:

- Surface adhesion

- Conformability

- Tensile strength

- High shear and peel adhesion

- Resistance to plasticizer migration

- UL746C recognition

GENERAL SPECIFICATIONS FOR 3M™ VHB™ TAPE

THICKNESS

Material Composition

Temperature Resistance Range

Use Cases by Industry for 3M™ VHB™ Tape

With 3M™ VHB™ tape, you can unlock greater design flexibility while meeting the rigorous demands

and standards of your industry.

Transportation: Automotive & Specialty Vehicle

- High-strength bonding for vehicle accessories, emblems and control panels

- Panel-to-frame and stiffener-to-panel bonding is simplified – no screws, rivets or welds.

- Sealing and vibration damping to enhance user experience

- Low odor and low VOC options available for interior applications

CONSTRUCTION

- Facade and architectural panel bonding

- Structural glazing solutions

- HVAC systems assembly

- Elevator panel attachment

- Panel to frame applications

ELECTRONICS & APPLIANCES

- Bonding components in electronic devices

- Moisture-sealed nautical navigational systems

- Decorative material attachment

- Attach plastic and metal emblems to powder-coat paints

- Attach tempered glass to metal and plastic frames

- Low odor and FDA applicability for indirect food contact applications per 21 CFR 175.105 are now available

SIGNAGE AND DISPLAY

- Mounting and bonding of signage elements

- Sealing of electrical components

- Application of decorative panels to rigid frame for support

- Large lens bonding

Common Applications for 3M™ VHB™ Tape

Bonding

Most higher surface energy substrates, including metal, glass and HSE plastic. Variety of plastics and paint systems. Dissimilar materials, including metal to plastic, metal to glass, aluminum to composite and composite to plastic.Mounting

Exterior and interior panels to frame Windows and doors. Vinyl wiring ducts and conduit channels. Seam vinyl banners Polycarbonate lens over LCD.Sealing

Provides exceptional weatherproofing, protects against wind, rain, debris and UV rays. Anywhere a watertight seal is needed.

iD Products Solutions with 3M™ VHB™ Tape

Looking for exceptional bonding tailored to your needs? The experts at iD Products are here to help you find, design and conquer with 3M™ VHB™ Tape.

TAILORED BONDING SOLUTIONS

Getting the right fit of your 3M™ VHB™ tape is critical to long term performance. Our experts are equipped to help you pinpoint the precise fit for your product.

3M™ PREFERRED PARTNERSHIP

We provide access to the best 3M™ products, technical expertise and support, including customer application testing.

RAPID PROTOTYPING

We keep your project progressing from concept to launch.

DIE-CUTTING

With our capabilities we can mass produce both simple and complex designs for custom applications. Parts can be kiss-cut to a liner, supplied on sheets or rolls or with pull tabs for ease of use.

TIGHT TOLERANCES

Because of its rigid properties, 3M™ VHB™ Tape can be cut for narrow and complex designs, particularly for the electronics industry.

CERTIFIED FOR YOUR INDUSTRY

iD Products is ISO 9001:2015 Certified, UL, CSA, RoHS & REACH. A Certificate of Compliance is available upon request for all shipments.

Unlock New Possibilities with 3M™ VHB™ Tape Solutions by iD Products

Achieve a slim design that seals out moisture, dust and debris with the power of 3M™ VHB™ Tape. Start building better products with the industrial strength tape that’s exceptional and versatile.