What are graphic overlays? A guide for OEM and industrial design applications.

When your device or equipment goes to market and into the homes and workplaces of your end users, the stakes are high. And your graphic overlay is the ultimate brand ambassador. That has a poetic ring, but it’s also practical.

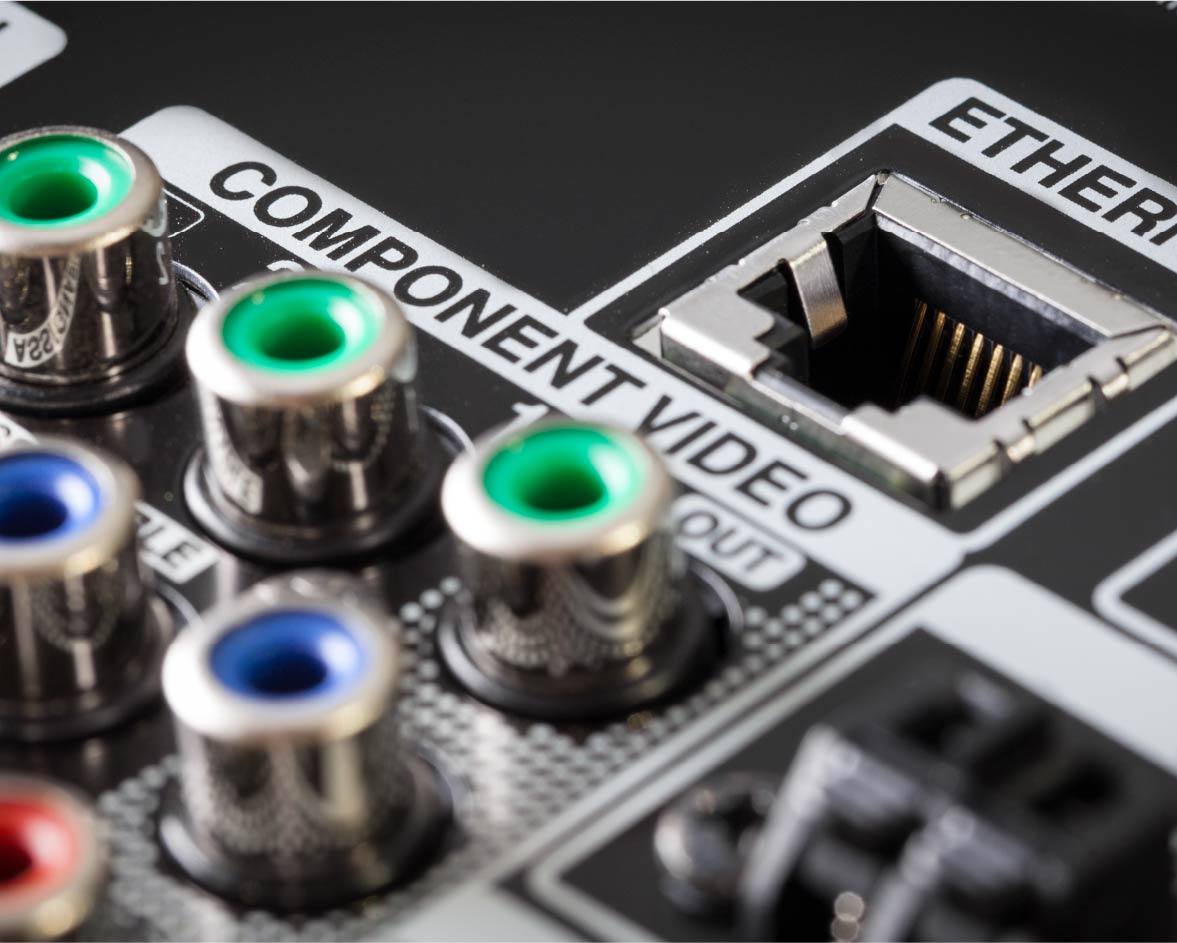

What is a graphic overlay? A graphic overlay is sometimes called a control panel overlay. While these terms have important distinctions, the overall purpose is the same: it’s where humans and machines connect, shaping the user’s experience with your product.

A well-designed overlay is intuitive, durable and supports productivity. A poor one creates confusion, downtime and frustrated users. In this blog, we’ll walk through the elements of a well designed front panel graphic overlay and how it supports industrial and OEM applications.

Where are graphic overlays used? Top applications

Graphic overlays are used anywhere equipment needs a clear, durable and user-friendly interface. Found in homes and in the workplace, here are some common applications:

- Industrial equipment – control panels for heavy machinery and automation systems.

- Medical devices – front panels and keypads for monitors, diagnostic tools and treatment equipment where clarity and sanitation are critical.

- Consumer and commercial appliances – washing machines, ovens, refrigerators and other products where overlays provide branded front panels and intuitive controls.

- Electronics – displays, instrumentation panels and portable devices that require compact but durable user interfaces.

- Transportation – dashboards, switches and cockpit panels exposed to vibration, sunlight and temperature extremes.

Making a graphic overlay that lasts

Graphic overlays provide visual and sometimes tactile information for the end user so they can use your equipment or device –– safely and effectively. Top qualities you want in your graphic overlay are clarity and durability. Those qualities are critical in demanding applications like medical devices and industrial equipment.

Visual elements of a graphic overlay

As the name implies, colors and graphics play a central role in overlay design. The graphic overlay provides the markings — or legends — on the control panel, including colors, text and icons that guide and communicate the various functions and controls to the end user. Logos and branding colors are often integrated into the design.

Overall, a strong graphic overlay design requires precise color matching and high-resolution printing to deliver crisp text and dynamic true-to-life colors.

In medical devices and industrial applications, reliable visuals do a lot of heavy lifting:

- They provide important cues, such as color coding and clear markers, that help reduce errors in rapid-response situations.

- They’re intuitive enough to keep users focused on the task at hand instead of playing trial and error with controls.

- They stand up to the environment — resisting wear, exposure and cleaning agents — ensuring the overlay performs reliably over time.

Tactile elements and why it matters in graphic overlays

A graphic overlay on a control panel can also feature tactile elements, often raised or textured surfaces that guide the user to the correct commands and functions. These features provide an added layer of usability. In low-light environments or for visually impaired users, this feature keeps equipment accessible and reduces the risk of errors.

Common tactile finishes include:

- Embossing – raised surfaces that highlight buttons or symbols.

- Debossing – recessed areas that define functional zones.

- Textured finishes – matte or patterned areas that create tactile contrast.

- Braille – raised dots for accessibility in compliance with ADA or other standards.

Creating durable graphic overlays

Graphic overlays are typically constructed with high performance films and protective coatings that serve a dual purpose: they safeguard the overlay’s graphics along with the underlying components in the device or equipment.

- For the graphics: These films and coatings help prevent fading, abrasion and damage from UV exposure, moisture and chemicals.

- For the equipment: overlays act as a barrier, shielding inner components from dust, liquids and other contaminants.

When paired with high-performance pressure-sensitive adhesives from 3M, a graphic overlay can even provide a complete sealing function while serving as the user interface. For global markets, industrial graphic overlays may also be manufactured to meet regulatory standards such as RoHS compliance.

Precision fit and integration of your graphic overlay

A great design falls flat if it doesn’t perfectly integrate with the unit. Even slight misalignment in fit can lead to gaps, peeling edges or interference with buttons and displays — all of which undermine device performance.

That’s why precision cutting is essential. Advanced die cutting and CNC routing ensure overlays meet exact specifications, matching the buttons, indicators and display windows.

Common precision processes include:

- Die cutting – ideal for producing high volumes of flexible materials with consistent shapes and smooth edges.

- CNC routing – used for rigid materials or complex designs that require tight tolerances and intricate cuts.

- Close tolerance registration – ensures graphics, legends and cutouts line up exactly where they belong.

- 100% scrap removal – keeps finished parts clean, accurate and ready for assembly.

With these capabilities, overlays do a better job of protecting your equipment while providing a polished, professional user interface.

Ready to get started on your front panel graphic overlay?

iD Products is a trusted graphic overlay manufacturer with the materials, advanced equipment and skilled technicians to support your design — from prototype to production.

Let’s talk. Contact our team to request a quote.